In the past, machining was all about reliability, precision, and speed. However, in the current business environment efficiency is a must. When you’re manufacturing automotive parts and aerospace components, or high-tech electronics, the tools you choose will directly impact your profitability. The indexable drill, the high-speed drill, the tungsten carbide inserts and threading tool are all making a difference.

These aren’t just updates to older tools. The new tools provide a more efficient way of working, which reduces the time it takes to work, decreases costs and delivers better results while working with less effort. We’ll take a closer at how they can help companies drill faster, cut more precisely and finish more quickly.

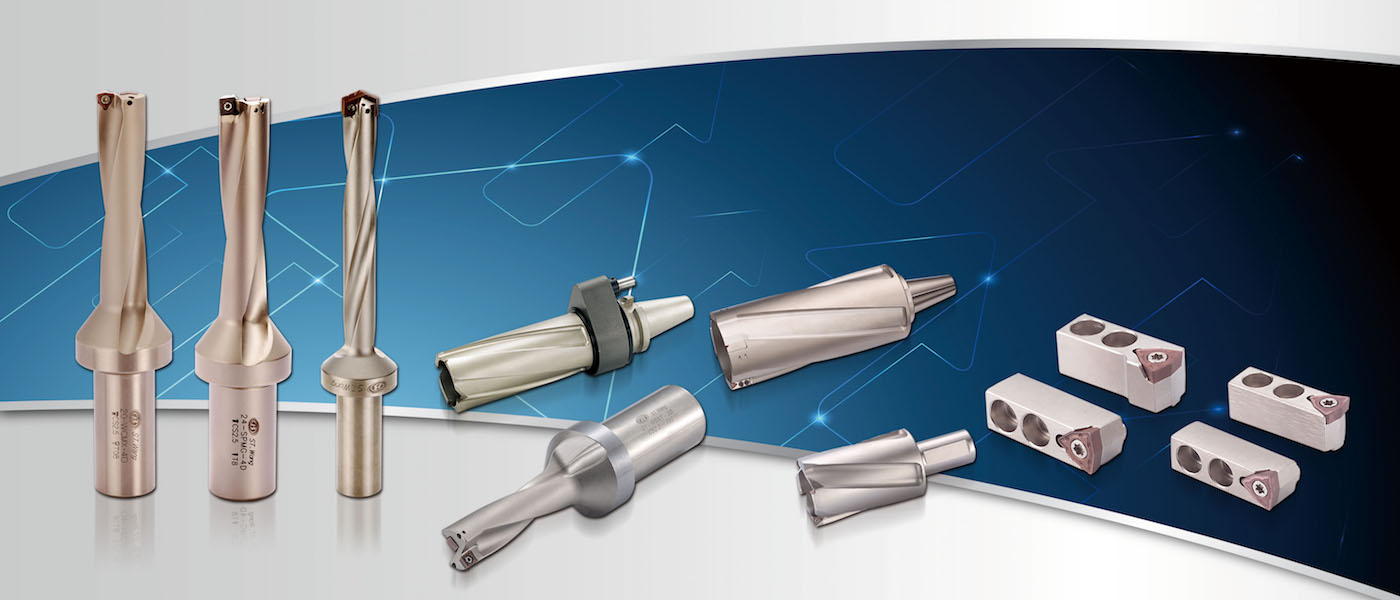

Image credit: stwang-tw.com

Indexable Drills: More Holes, Less Hassle

Drilling holes of a large size used to be time-consuming and costly. The solid drill was slow to wear down, required sharpening and could slow down production lines. This is the reason why more machinists have switched to indexable drills. It is possible to replace inserts, not the entire tool when it becomes dull.

Indexable drills are known for their efficiency. They’re built for long runs, performance that is heavy-duty and simple maintenance. It is possible to reduce loss, keep your tool inventory down, and increase the lifespan of your equipment with the use of replaceable inserts. SHANG TZANG WANG ENTERPRISE CO., LTD, offers modern core-stay drills for disposal that offer consistent performance even in large-diameter applications. This upgrade is suitable for shops that carry out repetitive drilling and machining of holes. It can save them hours each week.

High-Speed Drills for Modern Demands

High speed drills can be employed in a production environment where time is the most important factor. They are engineered to operate quickly and precisely without compromising on speed. These drills are ideal for materials with high resistance and short cycles. They’re employed in all kinds of medical devices, from precision to high-volume automotive parts.

Modern high-speed drilling machines feature modern coatings and optimised flute designs that reduce friction and heat build-up, helping to extend the life of the tool. This means less tool changes as well as less breakage, which means increased production. For anyone who’s experienced the frustration of a damaged drill in mid-cycle switching to a high speed drill is an amazing experience.

Tungsten Carbide End Mills: Reliable Performance Cut After Cut

When it comes to milling, tungsten carbide end mills are the workhorses of the shop floor. They’re renowned for their durability in addition to their heat resistance and capability to cut through tough materials without losing edge sharpness. They provide consistently good results, whether finishing small corners or roughing out large areas.

Their flexibility is what makes end mills made of tungsten carbide so unique. The different coatings, angles, and flute count can be adjusted to fit a variety of jobs, from aluminum to titanium. Carbide end mills are an most suitable choice for machinists who are looking for a durable and precise machine. They offer an ideal balance between aggressive material removal, and a clean surface finish.

Threading Inserts: Tiny Tools, Big Impact

Threads’ creation might appear to be a minor part of the process, but it’s actually among the most vital aspects. A bad thread could ruin an otherwise excellent part. It is essential to choose a threading insert of high quality. Small, interchangeable inserts are specifically designed to cut internal or external threads with extreme precision and repeatability.

Threading inserts are more stable than taps and dies. They deliver the same results over many cycles. The tool can be adjusted to the next cutting spot when one side is dull. There’s no need to take it off or re-grind. It’s quick, clean and cost-effective. Machinists value threading inserts not just for their speed but for their durability. With the right insert, you know the threads will be inserted correctly the first time no second runs, no need for reworking and there is no worry about part rejection.

The Bottom Line

Modern machining is highly time-sensitive. It’s impossible to waste time. Therefore, today’s most efficient manufacturing facilities are shifting to smarter, more adaptable solutions for tooling. These advanced cutting tools don’t just improve accuracy they simplify workflows, cut down on changeovers and extend the life of usable tools. What’s the result? It means that less time is spent in troubleshooting, so more time can be spent on producing high-quality parts. In an industry where higher requirements and a tighter margin are standard, having tools that truly function more efficiently gives manufacturers the edge they require to remain in the game.